Business overview-

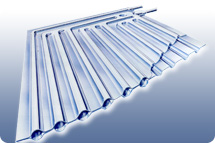

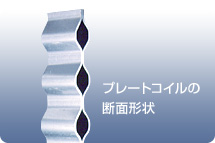

PLATECOIL

In the swiftly evolving industrial sector, each year there is a growing need for temperature control equipment. Such equipment must be able to efficiently heat and cool raw materials and chemical products with ever- lower energy consumption. PLATECOIL heat exchangers answer these requirements.

Our PLATECOIL product technology, with its unique press formed shapes, has been successfully commercialized in a variety of industrial sectors including the chemicals, food products and automotive industries for over forty years. In recent years, we have widened our scope of application to meet demand from a variety of sectors ranging from electronic materials and environment-related equipment to marine vessels and the nuclear power sector, demonstrating the reliable quality and high performance of our product.

-

PLATECOIL

dipped in tank

[ Dipping type ]

- High conductivity

- Thin and light plate

- Wide range of sizes available

- Installation and maintenance are easy

-

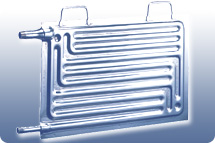

PLATECOIL

mounted around tank, without welding

[ Clamp-on type ]

- Can be installed on existing tank

- Can be installed easily

- Has a large heat transfer area

-

PLATECOIL

welded to tank (all-in-one)

[ Vessel tank ]

- High conductivity

- Capacity inside heat exchanger is small so it is possible to reduce the volume of heat transfer medium or refrigerant.

- Possible to lighten tank

-

PLATECOIL

mounted directly on drum can

[ Drum warmer(200L) ]

- Easy to move and install

- Explosion proofing not necessary

- Possible to take on and off

Note: It can be mounted on other equipment such as cylinders.